ISA-95 levels for Industrial Systems

One of the

first certification exams I applied was the ITIL Foundation 8

years ago, where I learnt about IT Service Management (ITSM).

Afterwards, I worked for Ariadnex to get ISO 20000, where I

learnt more about IT Service Management. I also worked for Ariadnex

to get ISO 27001, where I learnt a lot about Information

Security. These last two years I’ve also been working with PCI-DSS

and ISO 22301. I mean,

I think reading standards and applying

best practices is important, and much of the time, mandatory to do a

good job.

Today, I

want to write about a new standard I’m reading lately. It’s the

ISA99 standard. I didn’t know this standard till four or five

months ago when I started working on a new project. If you know the

ISA99 standard, you’ll know I’m talking about an

industrial project. Actually, the ISA99 committee has developed the

ISA/IEC 62443 series of standards and, then, the ISA99

standard is no longer developed by the committee. What I would like

to highlight today is the levels defined by the ISA95 and

ISA88 standards.

|

| ISA-95 levels |

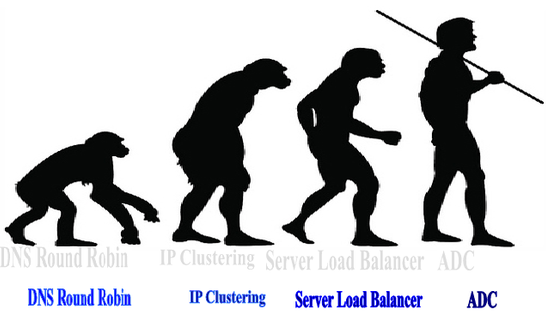

The first

two levels, level 0 and level 1, of process control are

focused on the control of equipments which execute the production

processes. On the one hand, level 0 is the equipment and human

resources which are required for the industrial process. Level 0 is a

set of physical assets into the enterprise. On the other hand,

automations-systems such as PLCs, DCSs or RTUs are in the level 1.

These automations-systems work with the physical assets, which are in

the level 0. The level 1 devices are electric and control devices.

The next

level, level 2, is very good defined by the ISA88 standard.

HMI and SCADA systems are in this second level. HMI are operation

monitors to control specific processes while SCADA systems are

applications to control and monitor the whole industrial system. As a

rule, a PLC is controlled by an HMI while lots of PLCs are monitored

with an SCADA system. Therefore, the first interaction between the

human being and the hardware is in the level 2.

|

| SCADA - Supervisory Control And Data Acquisition |

The next

two levels, level 3 and level 4, are well defined by the ISA95

standard. We have the Batch, Historian and MES in the third level.

The Batch is like an SCADA with databases for batch production. The

Historian is a database where industrial data is store. The MES is

the interface between the level 2 and level 4. Therefore, the level 4

is where the business intelligence is located. For instance, ERPs and

CRMs are in the level 4.

|

| MES - Manufacturing Execution System |

Once all

levels are defined, how can we protect an industrial enterprise? The

bottom levels can be secured with an Intrusion Prevention System

(IPS) with industrial signatures which block attacks against

communication protocols (e.g. Modbus, PROFIBUS, Conitel, etc) while

the up levels can be secured with Application Control and Web

Filtering. In addition, I would like to highlight the importance to

segment the network into zones.

|

| FortiGate Rugged |

Keep

learning and keep studying my friends!! All comments are welcome.

Commentaires

Enregistrer un commentaire